Electroplating on Plastic by SPC

Does your manufacturing operation involve the production of objects made of plastics such as ABS, polypropylene, Teflon or polycarbonate? Do you need to give these materials the ability to conduct electricity? An effective solution is to "metalize" these materials by adding a metal coating via a process known as electroplating on plastic. Sharretts Plating Company has the capacity to provide a cost-effective plating on plastic process that can meet your requirements. Metal plating plastic is one of our many metal finishing specialties.

Electroplating on Plastic Components

Electroplating, the process of “electrodepositing” dissolved ions of one metal onto the surface of another metal, has been a popular manufacturing technique for more than two centuries. Manufacturers in a wide range of industries make use of electroplating for purposes such as corrosion and wear protection, increasing surface hardness, promoting electrical conductivity and even improving the appearance of a part or component.

While electroplating is typically viewed as a “metal on metal” manufacturing technique, it is possible to electrodeposit metals onto other non-metallic objects as well. The process of plating metal onto plastic is now a widely accepted industrial practice that offers a number of crucial benefits for manufacturers everywhere.

Tracing the Development of Plating on Plastic

Plating on plastic first gained widespread use in the automotive industry in the 1960s and is still frequently used in the industry today. Innovative plating on plastic applications include providing finishes on fashion items such as shoes, as well as on consumer electronics products including laptop cases and cell phones.

The first commercial metal plating plastic process was developed in the early 1960s, primarily for use in the automotive industry. Automobile manufacturers were seeking ways to make their vehicles more fuel efficient, which led to the increased use of lightweight plastic parts and components. Electroplating served the purpose of “metallizing” these parts to give them the gleaming appearance that appealed to most car buyers of the era. A key advancement was the development of a reliable chemical process for the surface preparation of acrylonitrile butadiene styrene (ABS), a thermoplastic polymer that offers the toughness and impact resistance required for automotive manufacturing applications. The new process provided sufficient adhesion between the ABS substrate and the metal coating.

Watch Video to Learn More About Electroplating on Plastic

Request a free quote

For Plating on Plastics

Decline and Resurgence of the Plastic Plating Process

The use of plating on plastic continued to grow through the 1960s and well into the 1970s, as industries such as plumbing and electronics began to discover the many benefits of incorporating plastic plating into their manufacturing methods. However, changes in the automotive industry, primarily a reduction in the demand for bright finishes on interior and exterior parts and components, led to a decline in the use of plastic plating that lasted well into the 1990s.

In recent years, there has been a resurgence in the demand for plating on plastic in a wide range of industries, specifically in the North American and European markets. This can be attributed to a renewed desire for bright trim among purchasers of vehicles and other products. Additionally, improvements in quality and environmental compliance have made the plastic plating process a more viable manufacturing technique than before.

We've Perfected a Revolutionary Plastic ELECTROPLATING technique

While plastic on its own is not a naturally conductive material, electroplating on plastic is still achievable. Unlike metal objects or parts, plastic materials cannot be immersed in a bath and coated. Instead, a more specialized plating technique is required. At SPC, we have drawn upon our nine decades of electroplating expertise to develop an innovative process for electroplating on plastic that is the best in the industry.

Process of Electroplating on Plastic

Special preparation is necessary prior to plating on plastic. The material is initially etched in a chromic acid-based solution to enhance its adhesive capabilities. Any excess chromic acid that is produced must then be neutralized. A solution consisting of palladium and tin salts is then applied to the material. Next, the surface of the material is coated with either nickel or copper from an electroless plating solution. The palladium and tin salt solution serves as catalyst when combined with the nickel or copper. The material is now ready for electroplating using standard plating technology. Learn more about our industrial uses of electroplating here.

Another option is to apply a conductive paint to the plastic surface prior to commencing the electroplating process.

What Are the Benefits of Plating on Plastic?

The increasing popularity of the use of plastics and plastic composites in a wide variety of manufacturing processes has also led to a greater demand for plating on plastic. Plating plastic with a metal surface enhances the appearance of the material and creates the impression of higher quality. As a result, it is often selected when a highly decorative look is desired.

Additionally, plating on plastic can be an effective means of protecting a substrate against the forces of corrosion and make it more resistant to damage from chemicals used in the manufacturing process. In some instances, plating on plastic can increase the strength and wear resistance of the substrate.

As we’ve seen in the automotive industry, an important benefit of plating on plastic is that it can significantly enhance the appearance of the substrate. Most industrial plastics tend to have a dull finish. While colorizing the plastic can make it more visually appealing, it still will not produce the bright, shiny appearance that many product owners desire. While plating with chrome has long been a popular technique in automotive applications, the potential health hazards posed by the hexavalent chromium plating process has led many metal finishing providers to employ safer alternatives, particularly nickel plating.

Alongside appearance, plating onto plastic offers several other benefits for the item's physical characteristics:

- Corrosion and chemical resistance: Plating on plastic can be an effective means of protecting a substrate against the forces of corrosion and make it more resistant to damage from chemicals used in the manufacturing process.

- Increased conductivity: Electroplating can also give a non-conductive plastic surface the ability to conduct electricity, a property that is invaluable to the manufacturers of electronic parts and components used in automobiles, aircraft and a multitude of other products. A metal coating can also reflect potentially damaging light away from the surface of a plastic substrate and serve as a protective barrier against harmful gases and corrosion. Additionally, metallization can help to control the dissipation of energy.

- Increased structural strength: Electroplating can improve a part's overall structural strength for greater durability. This added strength is one of the top benefits of electroplating onto plastic. If strength is your goal, nickel plating can be a good choice since nickel can resist corrosion and improve the lifespan of products.

- Stable and low contact resistance: In addition to corrosion resistance, plating can also reduce contact resistance, so you can increase the part's resistance to wear, chemicals and corrosion.

- RFI and EMI protection: Electronic devices release electromagnetic interference (EMI) and radio frequency interference (RFI), which contribute to signal interruptions and equipment malfunctions. Plating adds a layer of protection to block these harmful EMI and RFI waves.

Plating onto plastic is a great way to add durability in a range of different environments. It offers protection for everyday wear from contact, as well as more robust defenses against chemicals and interference. Meanwhile, structural integrity is a significant advantage in many applications, and adding conductivity to plastic is a great way to increase the design flexibility of a part while maintaining the cost-effective nature of plastic construction.

What Types of Plastic Materials Can Be Electroplated Successfully?

While the initial success of plating on plastic was achieved with ABS — in fact, ABS still comprises approximately 90 percent of all metal plating plastic applications — effective techniques have been developed for plating on a wide range of plastic materials. Typically, plastics fall under one of two categories — thermosets and thermoplastics. These two plastic families differ in their response to heat and can present different challenges during the plating process:

| Thermoplastics | Thermosets |

|---|---|

| Acrylic | Araldite |

| Acrylonitrile Butadiene Styrene (ABS) | Bakelite |

| Nylon | Epoxy |

| Polylactic Acid (PLA) | Faturan |

| Polybenzimidazole (PBI) | Furan Resin |

| Polycarbonate (PC) | Melamine Resin |

| Polyether Sulfone (PES) | Novolak |

| Polyoxymethylene (POM) | Phenol formaldehyde resin |

| Polyether ether Ketone (PEEK) | Polybenzoxazine |

| Polyetherimide (PEI) | Polyester |

| Polyethylene (PE) | Polyester resin |

| Polyphenylene oxide (PPO) | Polyhexahydrotriazine |

| Polyphenylene sulfide (PPS) | Polyisocyanurate |

| Polypropylene (PP) | Silicone |

| Polystyrene (PS) | Urea-formaldehyde |

| Polyvinyl Chloride (PVC) | Vinyl ester resin |

| Polyvinylidene Fluoride (PVDF) | |

| Teflon (PTFE) | |

| Polyimide |

Which Types of Plastic Cannot Be Plated On Successfully

There are certain types of plastics that are not known for their ability to be plated on with great success such as the Valox product family. There are other types of plastic that can only be plated upon in a blended form. At SPC, we have the expertise to determine the "plateability" of the plastics used in your manufacturing operation, as well as the best metal required to achieve your objectives.

What Are the Best Metals to Plate Onto Plastic Substrates?

Plating on plastics can be achieved with various metals. Copper is the obvious choice when there is a need to enhance the electrical conductivity of the substrate. Gold or silver plating plastic can also be used to add aesthetic appeal to a plastic product. Nickel plating on plastic is also a widely implemented metal finishing industry practice.

It is possible to plate a variety of metals onto plastic including:

- Gold: Gold plating plastic parts will obviously improve their appearance. Gold also offers a number of additional benefits. Gold provides protection against corrosion and is such a good conductor of electricity that it is frequently used to provide a conductive coating on electronic parts and components. Additionally, gold’s excellent heat shielding properties make it suitable for high-temperature applications.

- Nickel: Because of nickel’s bright, metallic appearance, it can serve as a suitable — and less toxic —substitute for chrome when plating plastic automotive parts. Nickel also provides protection against corrosion and wear. Alloying nickel with other metals such as tin and tungsten can increase the hardness of the nickel deposit and enhance its corrosion and wear resistance capabilities.

- Copper: Copper is perhaps best known for its excellent electrical conductivity, which is why copper plating is such as popular choice for metallizing non-conductive metal surfaces. Copper plating can also be used as a heat stop-off for masking. A major benefit of copper plating is its relatively low cost, especially when compared to precious metals such as gold and silver.

- Chrome: Despite the fact that hexavalent chromium is a known carcinogen and is listed as a hazardous air pollutant by the U.S. Environmental Protection Agency, many metal finishing shops still use chrome for automotive applications. Chrome provides a smooth surface finish, good corrosion resistance and strong aesthetic appeal. However, the chrome plating process is highly complex and can consist of as many as 30 steps. Platers that use chrome to plate on plastic are also required to adhere to strict EPA regulations. *Please note that Sharretts Plating does not plate with chrome. This content is for educational purposes only.

In many plastic plating applications, it is necessary to deposit an undercoat onto the plastic substrate prior to electroplating in order to build thickness and promote coating adhesion. A process known as electroless plating is typically used to accomplish the task. Electroless plating differs from electroplating in that no electrical current is used to deposit the coating. Instead, deposition occurs via an autocatalytic chemical reaction. Nickel and copper are the two most commonly used metals for electroless plating, although techniques for gold and tin have also been developed.

Challenges of Plating onto Plastic

The inherent challenge with plating on a plastic substrate is that plastics do not conduct electricity. Therefore, the electrically charged metal ions produced by the DC current during the plating process will not adhere to the surface of a plastic work piece. Consequently, it is necessary to prepare the surface by depositing a conductive film prior to executing the traditional electroplating process. There are several techniques that metal finishers used to prepare and activate plastic surfaces for electroplating:

- Etching: The etching process was developed in the 1960s to promote adhesion when plating acrylonitrile butadiene styrene (ABS), a polymer that is used in the manufacturing of various automotive products, medical devices, electronic assemblies as well as household and consumer goods. Etching entails the application of a chromic acid-based solution to remove the butadiene component from the resin , which facilitates bonding with the metallic coating.

- Electroless plating: Electroless plating is an alternative form of plating that relies on an autocatalytic chemical reaction instead of electricity to apply the coating. Nickel and copper are the materials that typically serve as the base metal for the electroplating process. This technique also provides a uniform coating and enables the plater to control the coating thickness more efficiently.

- Corona discharge: A corona discharge is a physical process that generates ionized air, which reacts with the plastic surface to develop free radicals. The radicals subsequently react with the oxygen in the atmosphere to increase the plastic substrates surface energy and promote bonding.

- Flame treatment: The flame treatment technique introduces the plastic surface to a gas flame, which results in oxidation and increases surface energy. This technique must be implemented with extreme caution - exposing the substrate to the flame for more than a few seconds will cause warping.

- Plasma treatment: Plasma treatments are executed under a partial vacuum. They entail the activation of a gas plasma which produces "excited species" that react with the surface of the substrate. This technique typically promotes better surface stability than other chemical or physical treatment processes.

Overview of the Plastic Plating Process

The process of plating on plastic is somewhat different than traditional electroplating. There are a number of additional steps that must occur prior to the application of the metal coating. It’s essential to thoroughly clean the surface of the substrate to remove any dirt and debris that could negatively affect coating adhesion. The next step is etching the plastic substrate in a chromic acid solution to promote adhesion and then neutralizing any excess chromic acid.

After that, it is necessary to activate the substrate surface with a palladium and tin salt solution, which is followed by the application of the electroless nickel or copper coating. At this point, the metal coating can be applied using standard electroplating techniques.

Because of the difficulty involved with plating on plastic, it is necessary to closely monitor the process and perform troubleshooting steps as needed. Common issues include:

- Too high of a chromic acid concentration during etching, which can lead to insufficient adhesion.

- Too high of a plating bath temperature that can cause the plastic part to warp.

- Inadequate plating of part edges, which may be a sign that the temperature of the accelerator used to remove excess stannous hydroxide is too high.

- Overly shiny parts after etching, which is typically caused by an etching process that is too short.

Specific Plastic Plating Applications

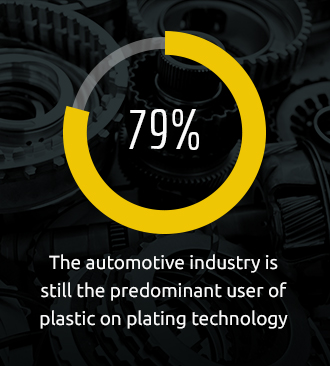

According to Global Market Insights, the automotive industry is still the predominant user of plastic on plating technology (79.2%), followed by domestic fittings (plumbing; 9.9%) and electrical/electronics (7.7%). Let’s take a look at some of the more common plastic plating applications in each of these industries.

Automotive

Global Market Insights indicates that polymers now account for approximately 15-20 percent of the total weight of interior and exterior car parts. In addition to the lighter weight, plastic parts provide additional design flexibility. The ability to mold and bend plastic into just about any shape gives engineers a wider range of options to develop vehicle styles that differentiate their company’s products from those of the competition. Manufacturers of OEM and aftermarket parts are also making widespread use of plastic plating.

As mentioned, nickel plating is now widely used to provide a bright, chrome-like finish on a variety of plastic car parts. According to the Nickel Development Institute, the largest application of nickel plating on plastics in the automotive industry is for decorative purposes to enhance the appearance of interior and exterior parts such as grilles, wheels, light bezels, emblems, gear shift knobs, door handles and bumpers. In some instances, a chromium-nickel alloy is used instead of pure nickel.

Nickel electroplating and electroless nickel plating can also provide functional benefits for auto manufacturers. The nickel coating can enhance the corrosion and wear resistance of certain plastic parts while also increasing lubricity, which is the ability to reduce wear that results from friction.

Electronics

The Nickel Development Institute states that electrical applications represent only a small portion of the market for plating on plastics. However, the plastic plating process does play a critical role in many electrical and electronics manufacturing procedures. In terms of decorative applications, nickel and nickel-chromium plating is used to enhance the appearance of the plastic trim on computers and mobile phones, as well as the various control knobs, switched and buttons on a wide range of home electronics and electrical appliances.

In terms of functionality, plating is used to make non-conductive plastic surfaces electrically conductive. In addition, plating provides a productive coating on electrical parts that are handled frequently or exposed to environmental conditions that could cause premature wear. The development of heat-resistance plastics has created a need for the nickel plating of connector blocks to enable direct soldering on their surfaces. Additionally, electroplating can play a key role in the production of circuit systems that feature interconnecting paths.

Plumbing

The use of plastic plumbing fixtures as a lightweight, inexpensive alternative to brass has created a demand for effective plating on plastic techniques. While the first plastic plumbing fixtures were typically made of colored plastic, the demand for brighter, shinier kitchens and bathrooms have helped pave the way for the use of metal-plated plastic products as a more viable alternative. Plated plastic plumbing products provide additional design possibilities and greater flexibility when compared to brass and offer hygienic benefits. The quality of plastic plumbing fixtures has continued to improve over time, too.

While nickel-plated plumbing fixtures can provide the desired aesthetics for many homeowners, applying a gold finish over the nickel coating can meet the needs of those who want a more elegant, upscale look for their bathrooms and kitchens.

Other Applications

- Heat resistant products: Plastic parts exposed to extremely high temperatures during manufacturing or end use can be vulnerable to heat damage. A metal coating can act as a thermal shield that minimizes the risk.

- Radio transmission products: Plating plastic antennas, RF filters or waveguides will protect them items when exposed to the elements and facilitate the transmission of radio signals.

- Hygienic products: Plating on plastics introduces sanitary qualities that are essential for products that require cleanliness and hygiene - a metal-plated plastic surface promotes easier, more efficient cleaning. Examples of products that fit this application include shower fittings, kitchen and bathroom accessories and washbasin taps.

- Household products: You can often find plated metal on the knobs and controls installed on various household appliances and electronic devices. Using metal-coated plastic is less expensive than manufacturing all-metal knobs, which enables manufacturers to offer their goods at more competitive prices.

- Apparel: If you've ever purchased clothing with metallic-looking buttons, there's a good chance that they consist of metal-plated plastic.

- Bottle caps: In France, some perfume manufacturers are now using plastic bottle caps plated with metal to make their packaging more attractive to prospective buyers. The metallic appearance adds a touch of elegance that makes the bottle stand out on a store shelf.

- Bar fittings: In the United Kingdom, metal-plated plastic is now a standard component for bar fittings and drink dispenser units.

Recent Plastic Plating Developments

Plating on plastic is still a work in progress, and new techniques continue to evolve. One recent development is a double layer nickel system featuring a semi-bright nickel coating underneath a bright nickel topcoat, which provides significantly enhanced corrosion protection. Another key innovation is a microdiscontinuous chromium system that increases the corrosion resistance of nickel/chromium deposits. Using these two techniques in tandem provides superior corrosion protection in extreme environments.

Tremendous strides have also been in the development of plastic resins that are used in conjunction with electroplating. The formulation of various ABS and polycarbonate blends has resulted in stronger plastic materials that also feature excellent ductility after plating. The latter characteristic is especially valuable in automotive industry applications in terms of facilitating the recovery of the plastic material after impact.

Sharretts Plating Company: The Best Choice for Your Plastic Plating Needs

Because of the many challenges involved with plating on plastic, it is important to choose a metal finishing company with extensive experience in this highly specialized area. SPC has been a leading metal finishing innovator since 1925. Over the years, we have developed and perfected a number of techniques that have helped to set the tone for the entire industry. This includes a revolutionary plastic plating process that can be customized for industries such as automotive, plumbing and electronics. We can also tailor the process to meet your unique plating requirements.

Contact Us to Learn More About Plating on Plastic

Sharretts Plating Company is an innovative plastic plating company that can help your business with all its electroplating on plastic needs. Our capabilities include a wide range of plastic plating services. We also have the expertise to help you select the most appropriate plastic plating service for your needs. Contact us today to learn more about what our plating processes can do for you! We can also provide a no-obligation price quote for our plating on plastic services.

Feel free to contact SPC if you would like to learn more about the benefits of plating on plastic, as well as our cutting-edge plastic plating process. We can schedule an on-site consultation to gain a better perspective of your company’s unique metal finishing requirements. We will also be happy to provide a no-obligation price quote for any of our premium metal finishing services.

Note: We do not provide cosmetic or decorative finishes.

Additional Resources:

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.