Does Gold Electroplating Make Sense For Your Electronics Manufacturing Operation?

September 30, 2015 | Stephen Sharretts | Share

Many of us think of gold in terms of its high monetary value and unmistakable aesthetic appeal. But this remarkable precious metal can also serve more practical purposes. The process of electroplating this soft, ductile, malleable metal onto other metal surfaces can offer important benefits, including enhancing corrosion resistance, improving electrical conductivity and shielding the object against intense heat. Despite its relatively high cost, gold plating is the preferred process in many industries, including electronics.

Gold Plating Applications in Electronics

Perhaps the most common gold plating process in electronics is the application of a thin coating of gold on connection points. Unlike most metals, gold doesn’t oxidize and lose electrons when exposed to oxygen in the atmosphere. This enables it to provide the smooth surface necessary for a reliable connection. Gold’s inherent softness also allows it to deform under pressure, which increases the size of the contact area. This ultimately results in better long-term connections.

Gold plating is also frequently used in the manufacturing of electronic circuit boards. A gold coating will provide corrosion protection and enhance the electrical conductivity of the underlying copper components. However, it is usually necessary to plate a barrier layer of another metal onto the substrate prior to plating gold onto copper, as direct gold-on-copper plating can cause tarnishing. Applying an electroless nickel coating prior to electroplating can accomplish this objective.

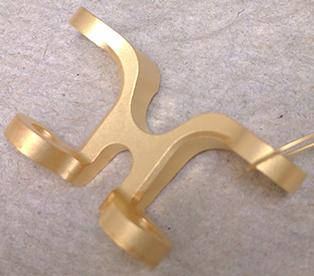

The semiconductor industry has relied on gold plating for many years. A layer of soft, 99.9 percent pure gold is used when parts must be wire-bonded during fabrication. Gold is also favored by semiconductor manufacturers because of its reflectivity, superior conductivity and excellent heat dissipation properties. Semiconductor components that can benefit from gold plating include top chucks, reflector rings and reflector arrays.

Is There a Cost-Effective Substitute for Gold Plating?

While gold is considered the “gold standard” in electroplating, its relatively high price point could make it too costly for electronics manufacturing operations that are on a tight budget. Silver can serve as a suitable substitute for plating electrical contacts. In fact, silver is actually superior to gold in terms of electrical conductivity, although it doesn’t provide the same high level of protection against corrosion and wear. Tin is an acceptable alternative in applications where improved solderability is required. Another viable option for plating connector contacts with bare edges is a palladium-nickel alloy with a flash of gold.

Sharretts Plating Company has extensive expertise in plating gold and other metals onto electronic parts and components. Contact us to learn more about whether gold plating is the best option for your electronics manufacturing operation.

Resources & Insights

Related posts

Explore articles similar to this one

Gold Plating Standards

Gold is known for its glitter and glamour, but it also has significant value from an electroplating perspective. Why should…

Learn more

Substrate Effect on Electroplating

How Does Substrate Affect Electroplating? Electroplating depends on the substrate to finish bonds properly and perform effectively. The substrate —…

Learn more

Manufacturing Brokers: Pros and Cons

Industrial manufacturing is a complex ecosystem. From part sourcing to shipping, building an effective supply chain requires reliable connections and…

Learn moreStay in touch