Industrial Gold Plating Services

When components break down in critical applications, the consequences go far beyond simple replacement. A corroded contact can ground an aircraft, a worn connector can shut down a production line, or an oxidized surface can compromise a medical device. Precision gold plating from an experienced service provider helps prevent these problems by delivering the long-term reliability these industries need.

SPC has been a trusted leader in industrial gold plating since 1925. We specialize in solutions for manufacturers who need superior accuracy, reliability and performance in everything they produce. Our clean facilities and advanced processes ensure every part meets the exact specifications your applications demand.

Quick Links:

Gold Plating Capabilities | Gold Plating Methods | Gold Plating Specifications | Gold Plating FAQs

ASTM B488, AMS2422 and MIL-DTL-45204 Compliant Gold Plating From SPC

Gold plating is not a one-size-fits-all solution. Understanding the benefits starts with knowing which plating type matches your application's requirements. Our ASTM B488, AMS2422 and MIL-DTL-45204 compliant processes cover an extensive range of specifications, from ultrapure soft gold for sensitive medical devices to hard alloy gold for high-wear connectors.

Type I, II and III Gold Classifications

Certain gold classes work better for engineering and manufacturing challenges, including:

- Type I: This 99.7%-plus pure, hard gold provides excellent protection against corrosion and low, stable contact resistance. It's suitable for applications requiring heavier plating thicknesses and superior properties, making it ideal for semiconductor packaging and precision electronics.

- Type II: This 99.0%-plus hard gold with nickel and cobalt alloys is engineered for high-wear applications like connector contacts and switch components. The added alloys increase hardness to 130 to 200 Knoop while maintaining high conductivity.

- Type III: This 99.9% pure, soft gold is the premium choice for implants, medical devices and other ultra-pure applications. It works exceptionally well for wire bonding applications and low-stress electrical contacts, while meeting strict biocompatibility requirements and offering the highest corrosion resistance.

Depending on the alloy content, our gold plating thickness standards range from 0.000005 to 0.002 inch (0.13 to 50.8 microns), thickness classes and 70 to 200 Knoop hardness grades. Each type can be applied over various underplates — including nickel, copper or palladium — to optimize adhesion and performance.

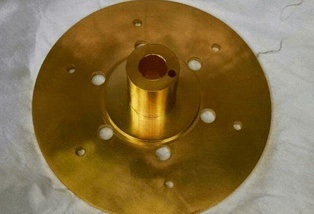

A Complete Range of Gold Plating Methods for Various Components

At SPC, we offer a complete lineup of solutions for your production needs, including barrel, rack and vibratory plating methods. Each process offers unique benefits for various materials and component types. SPC's engineers can help you determine the optimal gold plating process for your component's material, geometry and production needs.

Some of our methods include:

- Barrel plating: This process efficiently and effectively handles small, durable parts in high volumes. Parts tumble together in barrel-shaped baskets, making this method ideal for screws, pins and similar components that won't damage each other when they come in contact.

- Rack electroplating: Rack plating is ideal for delicate, large or more complex parts that need individual handling. Components mounted on custom fixtures are submerged in the plating solution without touching each other, receiving uniform coverage throughout the process.

- Vibratory plating: Vibratory plating combines the efficiency of barrel plating with gentler agitation. It's perfect for parts that need large-volume processing but are too fragile for traditional barrel methods.

Military and Industry Standard Compliance

SPC certifies every gold plating process to MIL-DTL-45204D, AMS2422 and ASTM B488 standards — the benchmarks for electronics, military, aerospace and the medical industry. Our documentation includes thickness measurements, adhesion test results, purity analysis and process certifications.

- MIL-DTL-45204D: As the U.S. military's gold plating specification, MIL-DTL-45204D sets strict requirements for gold purity, thickness and hardness to ensure reliability in mission-critical settings. This standard has a minimum gold purity of 99.7% and defines classes and types for different application needs, including high-wear and high-conductivity uses. SPC's gold plating processes are fully certified to MIL-DTL-45204D, providing traceable, specification-driven finishes for defense, aerospace and similar industries.

- AMS2422 plating: AMS2422 defines specific parameters for thickness, purity, adhesion and corrosion resistance, including a gold purity requirement of at least 99.0%. SPC's gold plating processes fully comply with these standards, delivering consistent quality for aerospace, electronics and precision engineering applications where electrical conductivity and resistance are critical.

- ASTM B488 gold plating services: ASTM B488 is the industry standard for electrodeposited gold coatings common in electronics, aerospace and precision manufacturing. It specifies gold purity, plating thickness and hardness classes, plus underplate requirements for optimal adhesion and performance. SPC's gold plating services meet or exceed all ASTM B488 criteria, delivering consistent, high-quality results for demanding industrial applications.

Industry-Specific Gold Plating Applications

Gold plating is critical in industries where electrical performance, corrosion resistance and reliability are paramount. Our engineers tailor each plating process to the specific technical requirements of every application. Common industries include:

- Gold plating for electronics and PCB components: Circuit boards and electronics rely on gold plating for reliable electrical connections. PCB edge connectors need corrosion resistance to prevent signal degradation over time. Semiconductor lead frames require wire-bondable surfaces that maintain consistent electrical properties through temperature cycling and high humidity.

- Military and defense applications: Military radar, guidance systems and ground support equipment operate in environments where failure is not an option. Gold's excellent conductivity and corrosion resistance help prevent the signal losses that could compromise mission success. Sensor connections in flight control systems depend on gold plating to maintain accuracy during vibration and temperature extremes.

- Medical device manufacturing: Medical applications demand the highest purity and biocompatibility standards. Implantable devices like pacemakers and defibrillators use gold plating on internal connections that must function reliably for decades inside the human body. Other applications range from blood analyzers and imaging equipment to surgical tools and dental instruments.

Gold Electroplating Process and Quality Assurance

Our plating processes follow strict, controlled sequences across each phase, from surface prep and underplating to deposition and final inspection. We monitor quality at each stage to ensure consistent and accurate deposition and adhesion.

Our Technical Process

Clean surfaces are paramount — any contamination can cause plating defects that compromise performance. Surface preparation removes oils, oxides and other contaminants that prevent proper adhesion. Depending on the material and plating process, parts undergo alkaline cleaning, acid activation and mechanical preparation when needed.

Underplating is the foundation for effective gold adhesion. Nickel underplates offer hardness and wear resistance, while copper provides excellent conductivity. Palladium can act as a diffusion barrier that prevents underlying metals from migrating through the gold layer over time.

Gold deposition happens in our climate-controlled environment. Temperature, pH and electrical current density affect deposit properties like hardness, grain structure and stress levels. Our automated systems continuously monitor and adjust these parameters to maintain consistent results across every production run.

Following the plating, parts may undergo a pore blocking treatment upon request. We dip the components into a specialized solution to seal microscopic pores in the gold layer. The pore blocker increases corrosion resistance by preventing base metals from migrating to the surface.

Postprocessing includes hydrogen embrittlement relief for high-strength steels and final inspection under controlled lighting. Parts receive final cleaning to remove any plating solution residues that could cause problems during assembly or service.

Testing and Verification Methods

Thickness measurement uses X-ray fluorescence (XRF) for non-destructive testing and microsection analysis for detailed verification. XRF provides fast results for production control, while metallographic cross-sections show the entire coating structure, including underplate thickness and interface quality.

Adhesion testing uses tape pull, bend and thermal shock methods that follow ASTM B571 standards. These tests simulate the stress parts will experience during manufacturing and their service life. Only coatings that pass all adhesion requirements move forward to final inspection.

Purity analysis uses X-ray photoelectron spectroscopy (XPS) and energy-dispersive X-ray spectroscopy (EDS) to verify the composition of the gold plating. These techniques can detect contaminants at parts-per-million levels to achieve compliance with the strictest specifications.

Salt fog testing according to ASTM B117 standards evaluates long-term corrosion resistance. Samples undergo hundreds of hours in salt spray chambers, accelerating corrosion processes and predicting how the parts will perform in harsh environments.

Technical and Engineering Support

Our process development services start with understanding your application's specific needs. When standard solutions don't match your requirements, we can modify the plating parameters, adjust the alloy content or recommend customized strategies that often lead to cost savings and increased performance.

Design consultation helps avoid common problems that cause plating failures. Simple changes like radius requirements, hole sizes or surface finishes can significantly improve coating quality and reduce manufacturing costs.

Failure analysis helps identify root causes when parts do not perform as expected in the field. Our lab equipment can determine whether the problems are caused by plating issues, material preparation or the environment. This analysis determines the most effective corrective actions while helping prevent future issues.

Gold Plating Technical FAQs

Browse the answers to common questions we receive about our gold plating services.

Does SPC Offer Biocompatible Gold Plating?

Our Type III gold meets USP Class VI biocompatibility requirements for medical device applications. We maintain segregated processing lines for medical parts and provide complete documentation supporting industry regulations.

When Should I Use Hard Gold vs. Soft Gold Plating?

Type II hard gold contains nickel or cobalt alloys that increase hardness to 130 to 200 Knoop, making it ideal for contacts such as connectors, relays, switches and circuit breakers. Palladium-nickel alloy plating is an excellent alternative for applications requiring similar characteristics at a lower cost. Types I and III soft gold range from 70 to 120 Knoop and work better for wire bonding, permanent connections and applications where you need easy formability.

What Are the Alternatives to Gold Plating?

Silver plating offers excellent conductivity at a lower cost but tarnishes over time. Palladium is another cost-effective alternative to corrosion-resistant gold plating, but it can be more complex to solder. Tin and other alloys work for many electronics applications but lack gold's long-term stability.

Gold's conductivity, corrosion resistance and reliability make it worth the premium cost for the most critical applications.

Can You Solder Gold-Plated Parts?

Yes, but the technique is critical. If too much gold is present, thin gold dissolves into solder joints and can create brittle intermetallic compounds. We typically recommend a maximum thickness of 0.000050 inch for soldered connections and proper flux selection to minimize the dissolution.

Find out More About Gold Plating With SPC

Do you want to learn more about how our gold plating services can benefit your business? Our engineers can review your specs and recommend the most practical and effective solutions for your production needs. Contact us online or call 717-594-9156 today to request a technical consultation, get a free quote or obtain additional information about our capabilities.

Additional Resources:

CONTACT SPC TO LEARN MORE ABOUT ELECTROPLATING WITH GOLD

Contact us to learn more about our gold and other plating options today!

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.