Plating with ruthenium offers many similar advantages to coating with other members of the platinum group of metals. This metal provides an inert finish that protects against corrosion, is bondable, provides high hardness and is conductive. With quality plating, it can produce a pore-free, mirror-like finish. The benefits of ruthenium electroplating make it an ideal metal for numerous industrial applications.

Ruthenium Plating Capabilities

SPC's plating capabilities with this platinum-group metal include thicknesses from 0.25 to 25.0 microns.

Ruthenium Plating Methods

The plating methods we use for this metal and other similar materials in the platinum group include the following.

- Barrel electroplating:This method works best for coating tough, small parts all at once in a barrel that turns during the electroplating process.

- Rack electroplating: Rack plating is preferable if you have large components that barrel plating might damage.

Ruthenium Plating FAQs

Plating with any metal brings questions about what that material can offer as a coating. Additionally, concerns often arise about the advantages and disadvantages of electroplating with ruthenium. We've provided the answers to these common questions and many others.

1. What is Ruthenium?

First discovered in 1844 by Russian chemist Karl Karlovich Klaus, ruthenium initially came from the Ural Mountains of Russia. Today, however, additional locations that produce this metal include sites in North and South America. While this metal is somewhat rare, its price does reach the levels of more precious metals.

Chemically, this material is a transition metal that naturally has a silver-white appearance. As a member of the platinum group, ruthenium exhibits many similar characteristics to its other family members. The platinum group includes platinum, palladium, rhodium, osmium and iridium.

All six of these metals exhibit chemical inertness, making them ideal coatings for applications that require durability against acid, chemical, heat and cold damage. These metals do not tarnish at room temperature. However, ruthenium will turn dark when exposed to potassium chlorate.

One of the best-known characteristics of this metal is its hardness. Ruthenium has a hardness ranging between 600 and 1,300 HK25, whereas platinum is only 150 to 550 HK25 and palladium is 75 to 600 HK25. The hardness of ruthenium is closest to that of rhodium, which ranges from 750 to 1,100 HK25.

Secondly, this metal features a high melting point of 4,082 degrees Fahrenheit, or 2,250 degrees Celsius. Such a high melting point makes this metal well-suited to high-heat applications.

Despite this metal's durability and heat resistance, it is both brittle and hard to cast, even heated, so it is not ideal for shaping into wires or other forms. However, it becomes highly useful in alloys and for electroplating onto other metals.

2. What's the Ruthenium Plating Process?

The ruthenium plating process uses electroplating to coat a prepared, metallic surface. To electroplate, workers attach the plating metal or alloy to a positive electrical connection. The base must have a negative current flowing through it. By submerging both substances into an electrolyte bath and turning on the current, atoms from the positive side will travel through the liquid and deposit onto the base material.

The processes for barrel and rack plating differ only in how the substrates connect to the negative current. With barrel plating, the barrel itself has a nonconductive surface. All the individual pieces tumble together in the barrel. Their conductive surfaces touch each other, producing a bipolar contact with the pieces they connect. This bipolar connection generates a more even coating over the substrate. If the parts can fit into a barrel, you can typically choose this method. However, if you have pieces with delicate parts or that need engineering precision in their plating, barrel plating may not perform to your needs.

By using springs, screws or wires, plating professionals attach larger or more delicate parts to a rack for rack electroplating. This holder protects components from tumbling in a barrel. This tool can also accommodate pieces that may not fit inside barrels. For parts that require the highest level of care during plating and an even coating across the entire surface, rack plating surpasses barrel plating. Many military and aerospace industry professionals choose rack plating for the superior results it offers. However, this method has higher labor requirements, and is therefore not as cost-effective as other electroplating methods.

Because electricity plays a crucial role in the electroplating process, the base layer's surface must be conductive. If not, as in glass, ceramic or plastic, it needs an electroless plated layer first before undergoing electroplating for its final coating.

3. What’s the Cost of Plating With Ruthenium?

As with all metals, the cost of using ruthenium for electroplating depends on supply and demand. Therefore, you may notice these costs fluctuate over time. This metal is less expensive to use as a finish than other rare materials. In many instances, it serves as a more cost-effective plating alternative to substances such as gold.

4. What Are the Benefits of Electroplating With Ruthenium?

Plating with ruthenium offers several benefits for the base material. By coating this metal onto a substrate, the base gains hardness, heat resistance and durability against corrosion and scratches. Like other platinum-group metals, this one provides a chemically inert surface that won't rust or wear off with regular use. Its long-lasting nature gives it an advantage over some surface coatings that more easily wear off or tarnish.

5. What Are the Advantages of Ruthenium Electroplating?

Though not used for aesthetic purposes in industrial applications, ruthenium still provides a more appealing coating. Compared to other precious metals, ruthenium's lower cost and attractive appearance have convinced many to use this as an alternative to less cost-effective options.

6. What Are the Potential Drawbacks of Electroplating With Ruthenium?

Though it offers numerous benefits, this metal does have a drawback. While it does not tarnish at room temperature or corrode in the presence of acids, it can turn black when immersed in a bath with potassium chlorate. For some applications that need an alternative to black nickel, this downside proves advantageous.

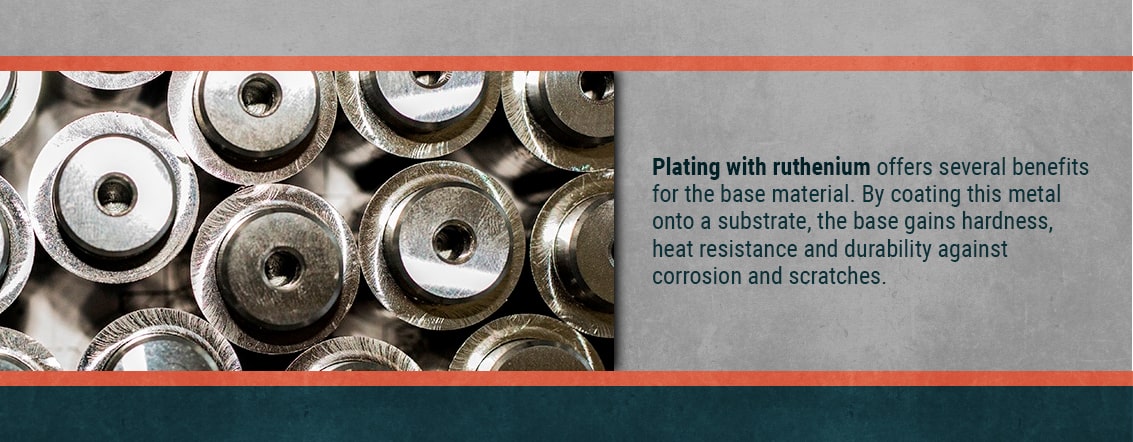

7. What Are the Industrial Applications of Ruthenium Plating?

Several industries make use of the extra durability provided by ruthenium plating. The aerospace, military and electronics sectors are only a few that frequently take advantage of ruthenium's inert properties, hardness and resistance to extreme temperatures. Specific uses of this metal within these industries include the following.

- Catalyst: In its natural form, ruthenium acts as a powerful catalyst to trigger chemical reactions. Frequently, it plays a role in splitting compounds of hydrogen sulfide.

- Data storage: This metal provides a robust surface for data storage devices, such as microchips and hard drive readers.

- Electrical contacts: Electrical contacts must hold up to regular use, while allowing electricity to pass through them. Ruthenium plating on electrical contacts allows for thinner coatings than using platinum or palladium alone. Plus, this plating costs less than gold or rhodium.

- Electrical resistors: This metal's resistance to corrosion also makes it an essential part of electrical resistors. While contacts must let electricity move through as quickly as possible, resistors slow the current. However, like contacts, resistors must avoid tarnishing and damage. Using this metal or an alloy with it prevents surface corrosion and wear on resistors.

- Fuel cells: This metal's ability to work as a catalyst led researchers to develop a possible alternative to platinum in fuel cells. When combined with graphene, ruthenium could help fuel cells convert the fuel into electricity in the same way platinum does.

- Semiconductors: This metal's natural durability and low resistivity have made it an ideal coating for electronics. Researchers have discovered that adding this metal to organic semiconductors boosted the conductivity significantly.

- Solar cells: Some compounds of this metal can absorb all visible wavelengths of light. This use of ruthenium could lower solar cell prices and make this energy source more accessible.

- Turbines: NASA uses this metal to create superalloys that withstand the extreme heat inside turbines. Turbine blades made from this superalloy became more durable and heat-resistant, while increasing the efficiency of the rest of the aircraft.

- Wiring: Using wiring with this metal or alloys of this metal proves superior to copper due to ruthenium's higher melting point and lower resistivity.

- Future supercapacitor electrodes: Due to its electrochemical capabilities, ruthenium dioxide could produce a cost-effective option for supercapacitor electrodes to meet future energy storage units' requirements.

8. What Are the Alternatives to Plating With Ruthenium?

Alternatives to ruthenium depend on the attributes of that metal that you most need for your product. For example, if you need hardness, rhodium is the platinum-group metal with the closest hardness rating to ruthenium. The former has a hardness from 750 to 1,100 HK25, whereas the latter's measurement ranges from 600 to 1,300 HK25.

For heat resistance, rhodium, again, has a similarly high melting point. For ruthenium, the melting point ranks among the highest of plating metals at 4,082 degrees Fahrenheit, or 2,250 degrees Celsius. Rhodium does not melt until 3,571 degrees Fahrenheit, or 1,966 degrees Celsius, making it the second-highest in the rankings of melting temperatures for finishing metals.

If your product requires a chemically inert, corrosion-resistant surface, most other platinum-group metals will fulfill that need. The exception is osmium, which oxidizes readily.

9. What Are Common Ruthenium Electroplating Issues?

With electroplating, unless the process happens in a carefully regulated environment, several problems could occur. These affect the final coating's attributes, including its durability and longevity.

First, a lack of preparing the surface can impact the electroplated results. For example, cold shuts happen when the molten metal cools before filling the product mold. The substrate has uneven mechanical strength, resulting in a weaker finished product. Another instance includes the presence of sharp edges on a substrate. The plating collects more heavily on these edges, becomes brittle and breaks off.

Secondly, the electroplating process itself can introduce problems. For example, a loss of adhesion of the coating may come from an expired pretreatment solution. Another issue happens when hydrogen gets into the plating and causes premature brittleness and breaking. Stress relief baking and other measures to mitigate the impacts of hydrogen can prevent this issue. Other issues include a dull coating or oxidation of the surface, resulting in poor adhesion of the finish.

Flaking is also a problem with numerous causes. It can happen when the part does not get proper surface preparation and pretreatment. Sometimes, inadequate electrolyte bath temperature control or the presence of contaminants can lead to flaking. Lastly, current interruptions and applying too thick of a coating can result in flaking or peeling of the finish.

10. What Are Tips for Troubleshooting Ruthenium Plating Issues?

The first step of any troubleshooting method is identifying the problem. Some issues, such as flaking and peeling, do not present themselves until the part goes under stress. To ensure excellent adhesion and a problem-free coating, engineers may put the component under testing to determine the quality of the finish.

To look for the presence of flaking, a worker performs various tests on the finished component. The part may undergo bend or heat-quench testing. The former test requires bending the part until failure. Through careful examination of the finish around the failure point under a microscope, professionals will look for visual indications of peeling or flaking. The heat-quench test heats the part, then cools it in a room-temperature water bath. Again, a visual inspection will reveal if the stress produced flaking or pitting.

Peeling or flaking problems require prevention, rather than correction. Monitoring the electrolyte plating bath chemistry and temperature will help ensure good adhesion and prevent flaking. Additionally, thoroughly cleaning and treating the substrate before plating will give the electroplating process the best results. Lastly, keeping the current consistent during the process will prevent flaking from an uneven electrical current. Interrupted currents require restarting the electroplating process.

Another problem that may occur is the presence of dull or hazy spots in the finish. Like flaking or peeling, cloudy spots appear from poorly controlled conditions during electroplating. Prevention works better than fixing these hazy areas. Just as flaking can occur from poor temperature control, inadequate or interrupted electrical currents, contaminations in the bath or poorly prepared parts, these factors can also cause dull deposits.

Contact SPC for Ruthenium Electroplating

Ruthenium, like other precious metals, offers many benefits for industrial applications. Its durability, corrosion resistance, hardness and cost-effectiveness compared to other platinum-group metals make it ideal for multiple uses.

When choosing an electroplating company, you need a business with equal experience in customer service and plating. SPC has both. We've been in business since 1925, providing our customers with superior plating for their products and service for them. If you want to learn how we can improve your parts with a coating of ruthenium, contact us for more information.

Additional Resources:

LEARN WHAT OUR MANY SATISFIED CUSTOMERS HAVE TO SAY ABOUT Us

"I would like to thank you for the help you have provided us in developing an electroless nickel plating technique on an unusual substrate. The sample platings you provided show that we should be able to reach our goals. I especially appreciate your willingness to take on an unusual job, with the uncertainties that that entails...We are looking forward to working with you in the future on our plating needs."

– Robert K.