Electroplating is a process that involves depositing a metal coating onto an object’s surface1 via an electrical current. This popular process is utilized in a variety of industries2 for several different applications.

Also known as vacuum deposition, vacuum metallizing involves creating a layer of metal3 on an underlying substrate that is typically made of another material. The metal coating material is heated until it vaporizes within a vacuum chamber.

To help you determine which may be the right process for your business, we cover everything you need to know about electroplating vs. metallizing.

What Is the Vacuum Metallizing Process?

Vacuum metallizing uses physical vapor deposition (PVD)4. This is a process that involves molecules or atoms of a thermal vaporization source reaching the substrate without colliding with residual gas molecules within the vacuum chamber. This chamber’s lack of pressure decreases the metal’s boiling point, allowing the vapor to condensate and create a layer over the substrate. The process could involve different heating methods, such as electron beams, resistance heating or plasma beams. The resulting metal layer varies in thickness up to several hundred nanometers5.

Vacuum metallizing typically occurs via PVD or chemical vapor deposition6. With PVD, the vapor that is used for the coating begins as a solid or liquid source. With chemical vapor deposition, the vapor derives from a chemical source.

What Is Non-Conductive Vacuum Metallization?

Non-conductive vacuum metallization (NCVM) is a functional coating7 exhibiting a metallic luster and low electric conductivity. An NCVM coating can be applied on cell phones and tablet computers without interfering with the radio-frequency signals these devices send and receive.

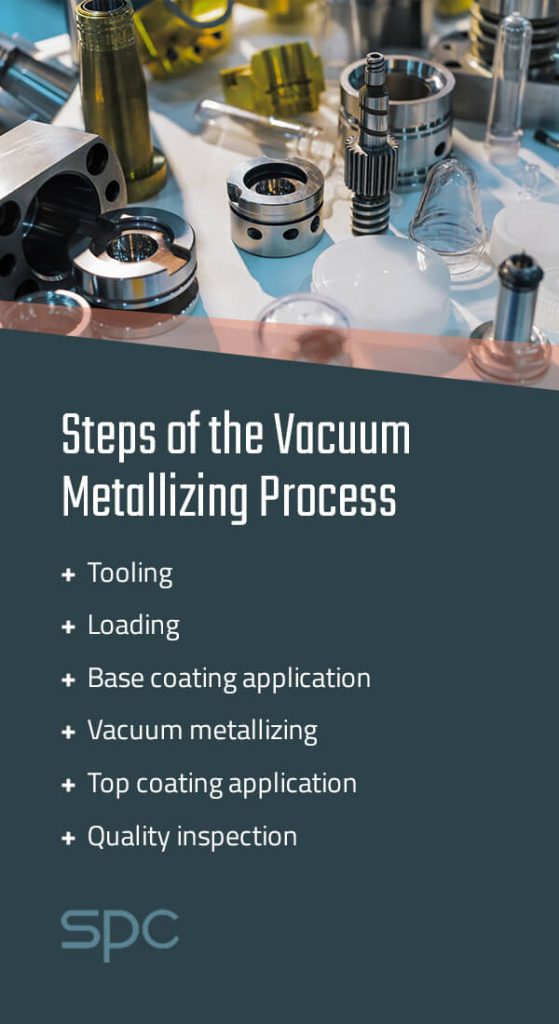

Steps of the Vacuum Metallizing Process

Here are the steps involved in the vacuum metallizing process3:

- Tooling: The first step is the tooling stage, in which an array is created to achieve maximum coverage of parts. Customized tooling fixtures are fabricated to hold parts in place for masking. Coating more parts each cycle may lead to lower costs.

- Loading: Strict loading procedures can reduce the risk of defects and contamination in the metallizing process. Pre-masking procedures are used during loading to decrease the need for manual masking and reduce the costs.

- Base coating application: This optional step prepares the part to receive the metal vapor properly. A base coating increases the part’s adhesive quality and leads to durable results.

- Vacuum metallizing: The metal is vaporized using a filament and vacuum chamber. The part is rotated precisely to ensure the metal vapor’s even deposition, creating a consistent thickness of the coating. In this step, the tooling from the first part of the process comes in to ensure the parts remain in place during the metallizing process.

- Top coating application: An optional top coat can improve the coated part’s properties. Some coatings may improve the resistance to abrasion, moisture and chemicals.

- Quality inspection: Before the parts can be released, they must undergo quality inspections. These inspections ensure the part meets current industry standards, such as AS9100, ISO/TS 16949 and ISO 9001.

What Is the Electroplating Process?

Also referred to as electrodeposition, electroplating involves depositing material with an electric current2. The electroplating process leads to the deposit of a thin layer of metal onto the substrate8. Primarily, electroplating is used to change an object’s physical properties and can be used to increase the wear resistance of the object, along with the thickness and protection against corrosion.

Electroplating can also be used to increase a part’s electrical conductivity, which increases its electronic function for devices. It also provides electromagnetic (EMI) and radio frequency (RF) interference shielding. These shields are very conductive and can carry current as a grounding type of application from stray current or voltages that need to be shed from the part itself. Additionally, electroplating can be used to carry current for the electronic device mounted to it, and is a conduit in many cases.

Parts of the Electroplating Process

An electric current is used in the electroplating process to dissolve the metal and deposit it. The main components of the electroplating process include:

- Cathode or substrate: The part of the electroplating circuit that needs to be plated is referred to as the cathode or the substrate. In the circuit, the cathode behaves as the negatively charged electrode.

- Power source: With a power source, a current can be added to the circuit. The power source introduces electricity to the system by applying a current to the anode.

- Solution: The electrolytic solution is where the electrodepositing reaction occurs. To facilitate the electricity flow, this solution contains metal salts like copper sulfate.

- Anode: The positively charged electrode known as the anode is a metal in the circuit that forms the plating.

When the cathode and anode are placed and connected, the power source supplies a direct current to the anode, causing the metal to oxidize. At SPC, we offer electroplating consulting services9.

Differences Between Electroplating and Vacuum Metallizing

There are some key differences between electroplating and vacuum metallizing. Compared to electroplating, the coatings from vacuum metallizing are extremely thin8. There are also differences in the metals used, applications, benefits and industries that use electroplating vs. vacuum metallizing.

1. Metals Used in Electroplating vs. Vacuum Metallizing

One of the biggest differences between electroplating and vacuum metallizing is the metals used in each process. Metals commonly used for electroplating10 include:

- Tin: Tin is a matte, bright metal that is highly resistant to corrosion and solderable. Tin is also environmentally friendly and affordable compared to other metals.

- Zinc: Zinc is highly resistant to corrosion and is often alloyed with other metals that enhance its corrosion resistance. When zinc is alloyed with nickel, for example, it is especially resistant to atmospheric corrosion.

- Gold: Gold is a precious metal that offers resistance to wear, tarnish and corrosion. Gold is also coveted for its conductivity.

- Silver: Though not as resistant to corrosion as gold, silver is highly malleable and ductile. Silver is a viable alternative to gold in applications that require electrical and thermal conductivity.

- Nickel: Nickel has great wear resistance that can be enhanced with heat treatment. The alloys of nickel are valuable, offering conductivity, hardness and elemental resistance. Electroless nickel plating is valued for its hardness, low friction, magnetism and corrosion resistance.

- Palladium: Palladium is a bright metal that may be chosen over platinum or gold for its beautiful finish, corrosion resistance and hardness. Palladium achieves excellent plating quality and hardness when alloyed with nickel.

On the other hand, vacuum metallizing commonly uses aluminum. This metal is reasonably conductive and the most plentiful metal on Earth11. Aluminum is also corrosion-resistant and cost-effective and retains the surface’s integrity. The high reflectivity of aluminum can also be useful in some applications.

2. Uses of Electroplating vs. Vacuum Metallizing

Some of the applications of electroplating differ from the common uses of vacuum metallizing. Uses of electroplating include:

- Protects the substrate: When a part with electroplated layers is in a harmful environment, the layer will break down before the base material. This protects the substrate from damage4.

- Lends surface properties: Electroplating allows the substrate to benefit from the properties of the metal with which it is plated. Metals vary in the properties they lend, such as improved electrical conductivity and protection against corrosion.

On the other hand, the uses of vacuum metallizing12 include:

- Insulation: One of the uses of vacuum metallizing is insulation. Film metallization can improve the radiation and reflectivity properties, giving insulation materials their functionality. Insulation systems can be used to protect spacecraft during critical space missions, for example.

- Improved barrier properties: Vacuum metallization can improve packaging and barrier properties for food, cosmetics, drugs and detergents.

- Hard coat: Vacuum metallizing can be used to hard coat surfaces.

3. Benefits of Electroplating vs. Vacuum Metallizing

Electroplating and vacuum metallizing differ in the advantages they offer. Benefits of electroplating include13:

- Heat resistance: Metals like gold are resistant to high temperatures, so they improve the substrate’s ability to resist heat damage. This can improve the plated part’s lifespan.

- Protective barrier: Electroplating results in a barrier on the substrate, which protects it from environmental conditions. This barrier can also protect against corrosion from the atmosphere in some cases. The protective barrier benefits components because parts last longer in harsh conditions and require less frequent replacement.

- Electrical conductivity: Copper and silver plating can improve electrical conductivity, offering an efficient, cost-effective solution that enhances the conductivity of electrical components.

Benefits of vacuum metallizing12 include:

- Safer: Vacuum metallizing tends to be safer than other processes like chromium plating. This is because vacuum metallization doesn’t require a dangerous mixture of cyanide and chromium.

- Cost-effective: Vacuum metallizing is often more cost-effective, making it easier to meet the needs of the end product or use.

- Increases hardness: Vacuum metallizing increases hardness and wear properties, and can create diamond-like hardness coatings. The increased hardness and heat resistance can help prevent wear and tear. Sometimes electroplating coatings have to be applied to certain base materials before the diamond-like coatings can be applied via vacuum metallizing because of an incompatibility of the material.

Similarities Between Electroplating and Vacuum Metallizing

There are some similarities between electroplating and vacuum metallizing, including a shared metal and industry.

Metal Used in Both Vacuum Metallizing and Electroplating

Both electroplating and vacuum metallizing use copper. Typically, copper is utilized for its heat resistance and conductivity as well as improving adhesion8 between layers of the material. Copper may be better for vacuum metallizing than aluminum because of its ability to provide a conductive surface that can mitigate surrounding electromagnetic interference (EMI). However, copper is also at risk of corroding and tarnishing.

Industries That Utilize Both Vacuum Metallizing and Electroplating

Vacuum metallizing and electroplating are used in the same industries. Industries that use both vacuum metallizing and electroplating2 include:

- Medical: Metal electroplating is often used in the medical industry to enhance the biocompatibility of components like implants. Titanium, silver and gold are used for their corrosion resistance, wear resistance, hardness and biocompatibility, which are all crucial for joint replacements and implants.

- Electronics: Gold plating is often used by electronic companies due to its conductivity and corrosion resistance. Gold plating is applied to connectors and semiconductors. Copper plating is a popular alternative to gold for conductivity purposes, while palladium alloys are used to provide a protective coating on electronic components and equipment.

- Aerospace: The aerospace industry often utilizes titanium for aircraft manufacturing. This is due to titanium’s high strength-to-weight ratio. The aerospace industry also uses copper to improve heat resistance, while nickel plating is used to protect against wear and corrosion.

- Oil and gas: The oil and gas industry uses electroless nickel plating to protect piping from corrosion, improving the longevity of parts.

Vacuum metallizing and electroplating are also used in several other industries14, including:

- Glassware and mirrors

- Appliance components

- Vapor barrier protection

- Chrome plating replacement

- Cosmetics and product packaging

- Industrial, commercial and residential lighting

Electroplating is used frequently in the automotive industry2. In harsh environmental conditions, electroplating can prevent corrosion. A zinc-nickel plating solution, for example, can prevent the formation of rust. An electroless nickel plating, on the other hand, can be an excellent alternative to chrome on plastic parts and catalytic converters.

Vacuum metallizing is used for vehicle lighting and components. The automotive industry also uses aluminum to mirror polish a surface and metallize it to test its optical reflectivity. Vacuum metallizing and electroplating can both be used for reflective and optical applications. For example, vacuum metallization is used for optical lighting parts like reflectors for vehicles and bicycles.

Electroplating vs. Vacuum Metallizing Plastics

Electroplating and vacuum metallizing both impact plating onto plastics. Since plastic is not conductive, direct electroplating is impracticable and the process is instead performed in steps. When coating plastics, vacuum metallizing and electroplating are sometimes used together.

Vacuum metallization involves directly depositing a metallic layer onto the plastic substrate15. This process is considered a cost-effective solution15 compared to electrostatic discharge (ESD) suppression technologies or electromagnetic interference (EMI) shielding.

Electroplating vs. Vacuum Metallizing Refractory Metals

Tungsten is one refractory metal known for its high resistance to wear, electrical conductivity, high melting point, robust chemical stability and radiation hardness. By coating materials with a layer of tungsten, the material can gain these benefits. One approach to doing so is electroplating. As an inexpensive process used to coat substrates16 with metals, electroplating is a popular method.

Electroplating vs. Vacuum Metallizing Ceramics

Electroplating and vacuum metallizing both impact plating onto ceramics and are sometimes used together when coating ceramics. To develop a surface capable of undergoing electroplating, you must first coat the ceramic with electroless nickel. This process involves the following steps17:

- Cleaned: The material must first be cleaned to remove debris, dirt and dust.

- Catalyzed: The material should then be submerged in a bath of electrolytes. These electrolytes are catalysts that lead the nickel to coat the ceramic.

- Electroplated: Finally, the ceramic is electroplated with a metal like copper, silver or gold.

Electroplating onto ceramics tends to be more complicated than electroplating onto metals. However, electroplating onto ceramics can improve conductivity, durability, functionality and corrosion resistance.

Vacuum metallization allows the ceramic to bond18with a metal part. During the brazing process, the ceramic’s chemical bonding metallization creates a wettable surface that enables the flow of braze alloy between the components.

Request a Quote From SPC

At SPC, we conduct industrial plating and metal finishing services. We have a state-of-the-art facility and equipment, intensive industry knowledge and the capabilities for plating onto unique surfaces. We serve many industries, including:

- Medical

- Hardware

- Aerospace

- Electronics

- Automotive

- Semi-conductor

- Telecommunications

We stand apart with our ability to plate metals onto plastics. With our experience that dates back to 19251, SPC engineers can determine the right coating and finish for your industry and end product. Request a quote19 from SPC today.

Sources:

- https://www.sharrettsplating.com/about/

- https://www.sharrettsplating.com/blog/what-electroplating/

- https://www.vacuum-metalizing.com/what-is-vacuum-metalizing/

- https://www.sciencedirect.com/topics/chemical-engineering/vacuum-deposition

- https://www.nisshametallizing.com/en/how-does-metallized-vacuum-vaporisation-work

- https://www.sciencedirect.com/science/article/pii/B9780857094681500013?via%3Dihub

- https://www.sciencedirect.com/science/article/abs/pii/S0167577X14010015#:~:text=A%20non%2Dconductive%20vacuum%20metallization,but%20a%20low%20electric%20conductivity.

- https://web.archive.org/web/20110720153833/http://www.newmoa.org/prevention/p2tech/TriChromeFinal.pdf

- https://www.sharrettsplating.com/additional-services/consulting

- https://www.sharrettsplating.com/coatings/

- https://www.deepcoat.com/common-materials-used-for-vacuum-metalizing/

- https://waykenrm.com/blogs/vacuum-metalizing/

- https://www.sharrettsplating.com/blog/benefits-of-electroplating/

- https://vergason.com/services/vacuum-metalizing/

- https://www.sciencedirect.com/science/article/abs/pii/S0042207X08001036

- https://www.osti.gov/pages/servlets/purl/1369449

- https://www.sharrettsplating.com/blog/plating-on-ceramic-vs-metal/

- https://www.asminternational.org/documents/10192/1899146/amp16510p035.pdf/7a3d5d88-2d37-4a9c-ab27-b956e01b3046

- https://www.sharrettsplating.com/quotes/