Selecting the right plating finish is critical in semiconductor manufacturing.1 Whether you are designing printed circuit boards (PCBs), microprocessors or electronic components, the choice between electroless nickel immersion gold (ENIG) and electroless nickel electroless palladium gold (ENEPIG) can impact solderability, wire bonding capability and durability.2

This guide breaks down the properties, benefits and considerations of both plating finishes.

Properties and Composition of ENIG

ENIG PCB finish is widely used in semiconductor applications due to its excellent balance of conductivity, durability and solderability.3 Its structure consists of two layers — an electroless nickel layer followed by a much thinner immersion gold coating. This combination provides a smooth, flat surface for soldering and component placement.

ENIG’s performance is tied to its layered structure. The nickel layer serves as a barrier between the copper substrate and the external environment. The gold layer is thinner and functions as an oxidation barrier to protect the nickel and acts as the primary solderable surface. IPC-4552 contains specifications for ENIG plating for PCBs — the electroless nickel layer must be between 3.0 and 6.0 microns thick, while the immersion gold layer must have a thickness of at least 0.05 microns.4

One of the most well-documented challenges with ENIG is black pad syndrome, a defect that occurs when nickel corrodes.5 This happens when the gold immersion process depletes the nickel, leaving behind a brittle, phosphorus-rich layer that cracks under stress. The result is poor solderability and field failures.

Manufacturers turn to ENEPIG to combat this challenge and meet the demands of complex and mission-critical applications.

Properties and Composition of ENEPIG

ENEPIG is a plating finish that builds upon ENIG by adding a palladium layer between the nickel and gold immersion. This additional layer serves multiple functions:

- Acts as a barrier

- Prevents nickel oxidation

- Diffuses nickel into the gold layer

Here are ENEPIG plating thickness specifications per IPC-4556:6

- Nickel: This metal is 3.0 to 5.0 microns thick. It provides structural support and acts as a barrier to prevent copper migration.

- Palladium: The palladium coating is 0.05 to 0.1 microns and serves as a protective barrier that prevents corrosion.

- Immersion gold: The gold layer is 0.03 to 0.05 microns thick and offers oxidation resistance for excellent solderability and long-term stability.

ENEPIG’s palladium layer also ensures reliable gold or copper wire bonding.7 This makes it preferable in applications where both technologies are used because the bond interface remains clean and defect-free. The ENEPIG wire bonding process involves the following steps:

- Surface preparation: The plated surface is cleaned to remove contaminants and strengthen cohesion.8

- Ball formation and bonding: A fine gold or copper wire is heated and pressed onto the ENEPIG surface to create a stable connection.

- Bond strength testing: The integrity of the bond is assessed to confirm reliability and performance.

Plating Processes for ENIG and ENEPIG

The plating processes for ENIG and ENEPIG involve electroless deposition for uniform coverage.9 However, because ENEPIG introduces an additional palladium layer, tighter process controls are required to balance solderability and wire bonding performance.

Here are the steps involved in both processes:

- Surface preparation: The PCB’s copper surface is thoroughly cleaned to remove oxidation. A micro-etch step roughens the surface to improve nickel bonding.

- Electroless nickel deposition: The board is immersed in a nickel plating bath, where a chemical reaction deposits a uniform layer of nickel onto all exposed copper areas.

- Immersion gold layer: The nickel-plated board is placed in a gold solution, where the immersion process replaces nickel atoms with gold.

- Electroless palladium: In ENEPIG, palladium is deposited onto the nickel surface to prevent corrosion.10 The metal enhances wire bonding and stabilizes the soldering surface, improving wetting and joint reliability.

- Rinse and dry: Both processes require a thorough rinse to prevent contamination.

The only difference between the ENIG and ENEPIG PCB finish processes is that the ENEPIG process requires depositing palladium onto the nickel surface.

Advantages and Disadvantages of ENEPIG in Semiconductor Applications

ENEPIG is suitable for many applications. However, like any surface finish, it has perks and considerations that decision-makers should know.

Advantages of ENEPIG

Here are nine benefits of ENEPIG:

- Cost-effective: While ENEPIG has a higher material cost than simple finishes like ENIG, it offers a cost-effective alternative to gold plating.11 Gold plating may require thicker layers to achieve the desired properties, leading to notable expense. ENEPIG uses a thin immersion gold layer for equivalent corrosion resistance and durability. This precise use of precious metals results in a more economical solution for applications where both performance and cost are critical concerns.

- Superior wire bonding strengths: ENEPIG enables robust wire bonding for both gold and aluminum wires — a capability that sets it apart from ENIG. Since the integrated palladium layer acts as a barrier, it prevents the formation of brittle intermetallic compounds at the bonding interface.12 This results in secure, consistent bonds essential for high-performance integrated circuits, memory chips and other semiconductor components.

- Shelf stable: One of ENEPIG’s key benefits is its ability to maintain a stable, high-quality surface over extended periods. The carefully engineered palladium and gold layers provide excellent resistance to oxidation, ensuring that components remain in prime condition until assembly. This stability is vital in industries where components may be held in inventory for long durations.

- High thermal durability: ENEPIG can endure the rigors of repeated temperature reflow processes without compromising performance.13 Its layered structure minimizes interactions between gold and nickel, which can otherwise lead to joint deterioration. By limiting intermetallic growth through a palladium barrier, ENEPIG maintains strong, reliable solder joints even after multiple thermal cycles.

- Eliminates black pad risk: Black pad syndrome has long been a concern with finishes like ENIG. ENEPIG eliminates this issue by interposing a palladium barrier between the nickel and gold layers. Devices benefit from more consistent and reliable solder joints.

- Excellent solderability with diverse alloy compatibility: ENEPIG’s versatility extends to its solderability across various solder alloys, including lead-free and traditional options.14 This broad compatibility is essential as the electronics industry moves toward environmentally friendly, Restriction of Hazardous Substances (RoHS) compliant manufacturing.15 By delivering consistent wetting and robust metallurgical bonds with various alloy types, ENEPIG supports diverse production needs without compromising performance.

- Compatible with fine-pitch components: As semiconductor components continue to shrink, surface uniformity and plating consistency become crucial. ENEPIG provides a uniform finish, reducing the risk of defects.

- Improves corrosion resistance: ENEPIG’s multilayer structure creates a formidable barrier against moisture, chemicals and oxygen. This improved protection preserves the integrity of the underlying materials, ensuring that the components can withstand prolonged exposure to corrosive elements without performance degradation, thereby extending the device’s lifespan.

- Broad material compatibility: ENEPIG is adaptable and compatible with various substrate materials and circuit designs, making it an attractive option for various applications. Its uniform and consistent plating process allows manufacturers to integrate into different production lines, supporting the evolving requirements of miniaturized and electronic assemblies.

Considerations for ENEPIG

While ENEPIG offers numerous benefits, manufacturers should keep the following in mind:

- Initial costs: ENEPIG involves multiple plating steps, which makes it more complex and costly than simpler finishes like ENIG. While its long-term reliability and performance benefits offset the costs, manufacturers with strict budget constraints may need to weigh these factors against their specific application requirements. For cost-sensitive projects, alternative plating solutions may offer a more economical balance between performance and affordability.

- Quality control: ENEPIG’s multilayer structure requires precise control over plating thickness and uniformity to ensure optimal performance. Variability in the deposition process can impact solderability and wire bonding if not carefully managed. Manufacturers need to invest in stringent quality control measures to maintain consistency. For applications where a simpler plating process is preferred, ENIG may provide a more straightforward production workflow.

- Potential for increased lead time: Because ENEPIG involves multiple plating steps, it may require a longer processing time than simpler surface finishes. This additional time can impact production schedules for high-volume manufacturing with tight deadlines. Companies should consider their turnaround requirements when selecting a plating solution.

- Environmental and regulatory compliance: ENEPIG involves using multiple metals and chemical processes. Companies must comply with industry standards while managing waste treatment and disposal.16

Advantages and Disadvantages of ENIG in Semiconductor Applications

ENIG also offers potential benefits and considerations.

Advantages of ENIG

The following are the perks of ENIG:

- Reliability: ENIG offers reliability in electronic assemblies.17 Its nickel-gold structure provides a stable, oxidation-resistant surface that supports good solder joints and performance. The finishing remains a trusted choice for designs where wire bonding is not required. However, ENEPIG is typically more reliable for demanding applications.

- Solderability: ENIG provides a uniform, smooth and planar surface. This flat surface ensures reliable soldering and assembly and reduces uneven solder joints.

- Durability: The nickel and gold layers act as a barrier against oxidation and corrosion, making it suitable for many applications, including playing a role in electromagnetic interference (EMI) shielding.18 However, ENEPIG might be the better choice for truly demanding environments due to the extra protection provided by the palladium layer.

- Process maturity: ENIG has been an industry standard surface for years because its processing techniques are well-documented and widely available. This may make it easy to source and implement with minimal specialized manufacturing expertise.

Considerations for ENIG

Before selecting ENIG, manufacturers should evaluate the following factors:

- Susceptibility to black pad: ENIG is prone to black pad formation, and this defect can compromise long-term reliability in mission-critical applications. Manufacturers must carefully control the plating process to minimize this risk.

- Limited thermal durability: ENIG can withstand multiple reflow cycles, but it is less thermally robust than ENEPIG because it lacks a palladium barrier. In applications requiring repeated soldering or exposure to high temperatures, the nickel-gold interface may degrade and compromise performance.

- Not ideal for gold wire bonding: ENIG is generally unsuitable for gold-wire bonding applications. For circuits requiring strong and reliable wire bonds, ENEPIG or gold plating is a better choice.19

Performance Comparison: ENIG vs. ENEPIG

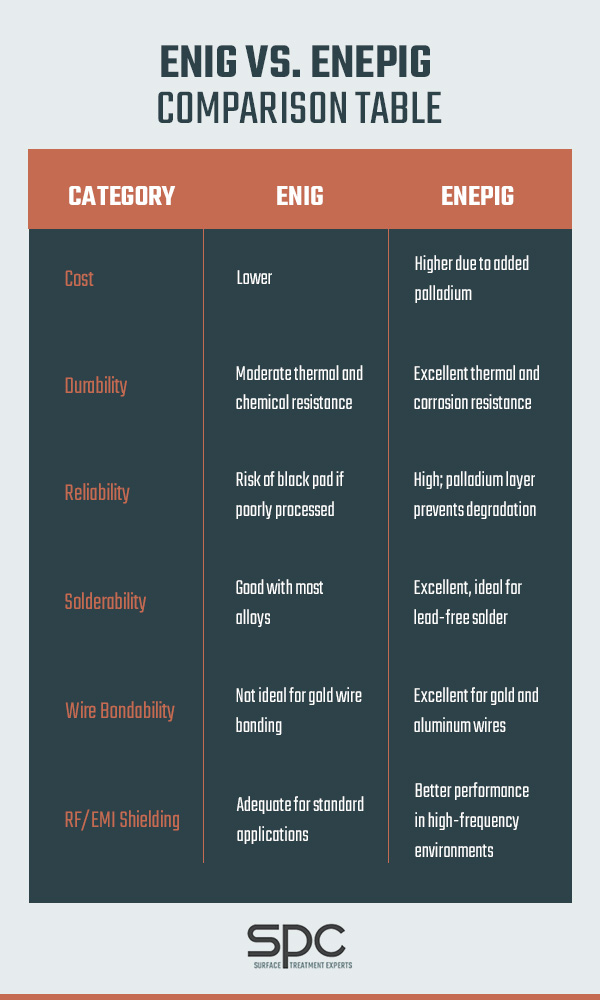

When comparing ENIG and ENEPIG in semiconductor applications, it is essential to consider the technical specifications and industry needs.

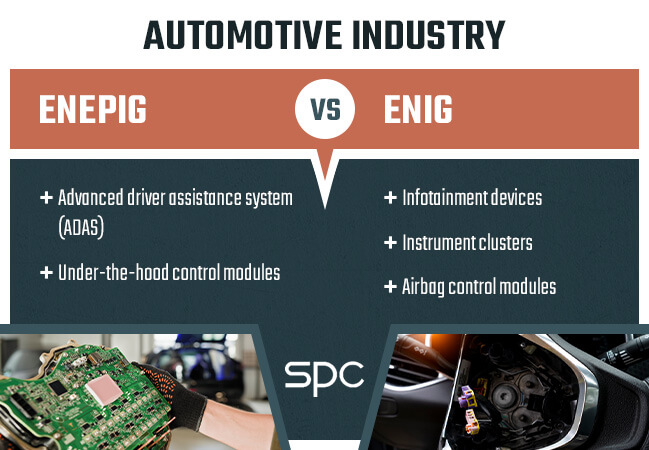

Automotive Industry

In the automotive industry, electronic systems are often exposed to heat and long duty cycles. Therefore, surface finishes must deliver durability, corrosion resistance and reliability.20

| ENEPIG | ENIG |

|---|---|

| ENEPIG is well-suited for under-the-hood control modules and advanced driver-assistance systems (ADAS), where thermal cycling is common. Its palladium layer offers strong corrosion resistance, minimizing joining degradation in high-heat, chemically exposed areas. It provides consistent solder integrity in high-reliability environments, where safety and control are paramount. | ENIG is a cost-efficient choice for infotainment devices, instrument clusters and airbag control modules. Its flat finish supports precise component placement, while good solderability ensures reliable connections in moderately demanding environments. |

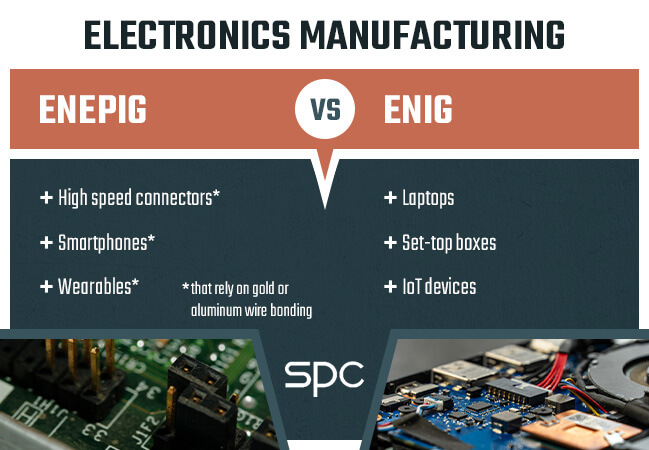

Electronics Manufacturing

For consumer electronics, the decision between ENIG and ENEPIG often boils down to fine-pitch components and wire bonding needs. As devices grow more complex, the surface finish must support wire bonding, multiple reflow cycles and electrical reliability.

| ENEPIG | ENIG |

|---|---|

| ENEPIG’s superior wire bonding properties make it ideal for high-speed connectors. It is excellent for smartphones, wearables and high-speed connectors that rely on gold or aluminum wire bonding.21 It offers thermal stability across repeated reflow cycles, critical in devices with multilayer board assemblies. ENEPIG provides clean, corrosion-resistant contacts, reducing the risk of signal degradation in high-performance applications. | ENIG is a reliable choice for laptops, set-top boxes and internet of things (IoT) devices. It offers flat pads and solid solderability, making it suitable for automated assembly at scale. ENIG performs well in applications where wire bonding is not required, helping manufacturers meet performance goals under tighter budgets. |

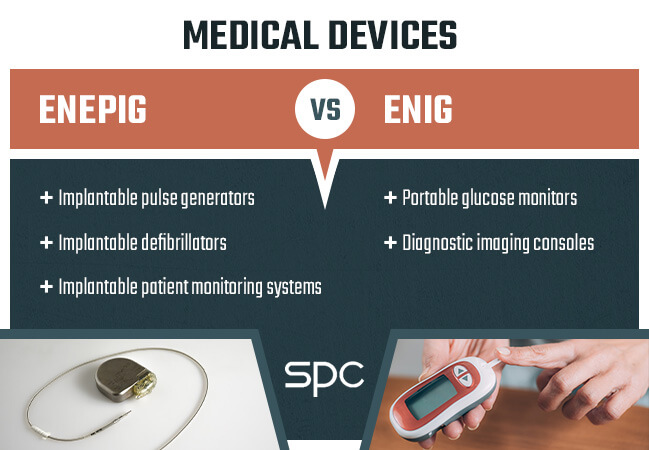

Medical Devices

In the medical industry, the emphasis is on using corrosion-resistant, biocompatible and reliable implantable and life-supporting devices.22

| ENEPIG | ENIG |

|---|---|

| ENEPIG is the preferred finish for implantable pulse generators (IPGs), defibrillators and patient monitoring systems. Its corrosion-resistant structure withstands exposure to sterilization cycles without degrading.23 The finish maintains stable wire bonds and solder joints throughout extended use cycles, making it suitable for mission-critical health care electronics. | ENIG is commonly used in portable glucose monitors, diagnostic imaging consoles and other nonimplantable devices. The finish offers reliable solderability and shelf stability, where implant-level performance is not required. ENIG provides a more cost-effective option for devices that demand electrical reliability and performance. |

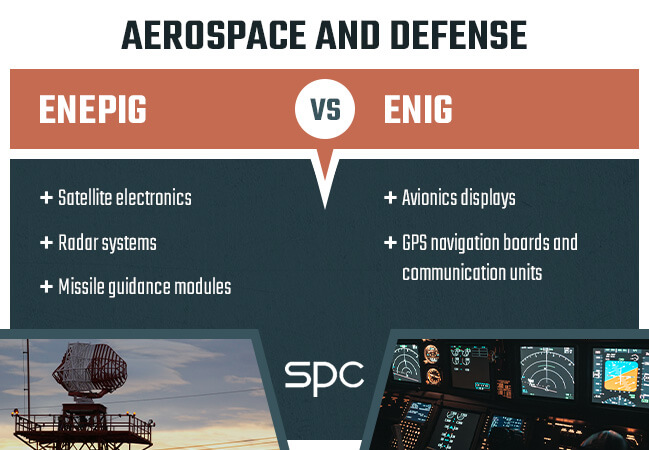

Aerospace and Defense

The aerospace and defense sectors require plating solutions that can perform under extreme conditions.24

| ENEPIG | ENIG |

|---|---|

| ENEPIG is frequently used in satellite electronics, radar systems and missile guidance modules. Its high thermal durability and resistance to corrosion maintain solder integrity under repeated thermal and mechanical stress.25 ENEPIG’s support for aluminum and gold wire bonding makes it suitable for high-performance systems. | ENIG is useful for avionics displays, GPS navigation boards and communication units. It provides good solderability and flat finishes for precise assembly, balancing performance with cost. |

Partner With SPC for Your Semiconductor Plating Needs

At SPC, we specialize in high-quality plating solutions for semiconductor applications. With more than 90 years of experience, we deliver cost-effective, high-reliability solutions that meet industry standards.26 Our operating environment ensures precision and consistency, while our expertise provides superior solderability, corrosion resistance and wire bonding performance. By outsourcing to us, you gain access to advanced process control and cutting-edge technology. Request a free quote today.27

Endnotes:

- https://www.sharrettsplating.com/industries/plating-semiconductors

- https://pmc.ncbi.nlm.nih.gov/articles/PMC8704334/

- https://www.e-jwj.org/journal/view.php?doi=10.5781/JWJ.2023.41.4.5

- https://www.ipc.org/TOC/IPC-4552wAm-1-2.pdf

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9740177/

- https://www.sharrettsplating.com/coatings/enepig

- https://www.mdpi.com/2072-666X/14/8/1538

- https://www.sharrettsplating.com/blog/what-is-electrocleaning/

- https://research.njit.edu/smart/electroless-electrochemical-deposition

- https://www.sharrettsplating.com/blog/plating-defense-against-corrosion/

- https://www.sharrettsplating.com/blog/electroless-nickel-plating-cost/

- https://www.sciencedirect.com/science/article/abs/pii/S0921509324007871

- https://www.sciencedirect.com/science/article/abs/pii/S0169433223008978

- https://ieeexplore.ieee.org/document/10173290

- https://environment.ec.europa.eu/topics/waste-and-recycling/rohs-directive_en

- https://www.epa.gov/rcra/resource-conservation-and-recovery-act-rcra-regulations

- https://www.sciencedirect.com/science/article/abs/pii/S0167577X20308090

- https://pmc.ncbi.nlm.nih.gov/articles/PMC9044480/

- https://pmc.ncbi.nlm.nih.gov/articles/PMC11050928/

- https://www.sciencedirect.com/science/article/pii/S2307187724000440

- https://jeas.springeropen.com/articles/10.1186/s44147-023-00309-2

- https://www.sciencedirect.com/science/article/pii/S2238785424002400

- https://pmc.ncbi.nlm.nih.gov/articles/PMC8704334/

- https://www.nature.com/articles/s41598-025-94508-x

- https://www.mdpi.com/1996-1944/14/24/7874

- https://www.sharrettsplating.com/about/

- https://www.sharrettsplating.com/quotes/