Disclaimer: Sharretts Plating does gold plating on industrial applications in large volumes. No single or decorative plating sales will be accepted.

Adding gold uses a chemical and electrical process called electroplating. You may see this referred to as Au plating or Au electroplating, because the symbol for gold on the periodic table of elements is “Au.” > > Gold Plating Services

WHAT IS ELECTROPLATING?

Electroplating is the process of coating one metal or metal object with a very thin layer of another metal, typically by applying a direct electric current. This partially dissolves the metals and creates a chemical bond between them. The coating applied by electroplating is usually around 0.0002 inches thick.

By creating a chemical bond, the plating is a permanent addition to the surface of the base metal. This means that it will not naturally fall off or separate. However, plating can be worn off over months and years of use and wear.

Because this top layer is so thin, it has very specific uses. Some metals are used as a coating, because they give added protection from rust, damage or corrosion.

HOW ELECTROPLATING WORKS

The Ancient Greeks used to mechanically attach gold to other metals through heating metals and placing them together then rapidly cooling the combination. This was hammered into shape for statues, books and many other artifacts.

Modern gold plating, called gold electroplating, relies on a chemical process to combine various layers of metal into a solid piece with a layer of gold resting on the surface. Electroplating has been in use commercially since the 1840s and was heavily refined during the two World Wars.

In all gold plating, the part is polished and cleaned as thoroughly as possible before the electroplating process starts. Gold plating will look uneven and smudged if the surface is dirty, oily, scratched or otherwise damaged.

Modern electroplating begins with the creation of a metal salt using the plating metal, typically gold or silver. These salts are formed when an acid and a base combine and create a neutralization reaction. Metal salts are formed when positively charged ions of a metal are combined with an acid or with a non-metal. This salt is then placed in water and mixed together to form the “bath” for your component.

The component you’re plating is immersed in this bath and an electric current is applied to it. The current is directed to the component and dissolves the metal salts as it moves through the bath. Gold molecules ride the current and are deposited onto your component.

How long the component is left in its bath typically determines the thickness of the plating.

When you get gold plating done, there are decades of clean and refined practices behind you.

ELECTROPLATING

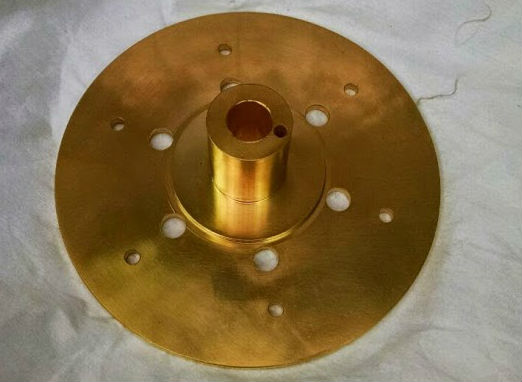

Gold plating can be added to almost any metal, including brass, copper or nickel. Silver items can also be gold-plated.

Some pieces will actually be plated with a wide range of metals even if you can only see the gold plating. If you have a silver component, for example, it will first be plated with copper because copper will make the plating tarnish slower. Then a plate of nickel will be added to improve the bond and strengthen the barrier.

This means that component will actually be a composition of silver, copper and nickel substrate layers with a final gold layer added on top.

Some newer methods involve using titanium nitride down as a rough layer, and then gold is electro-deposited into the roughness of this layer. This method gives a very full gold color but adds extra protection and a much longer lifespan to the gold plating.

RE-PLATING APPLICATION

If your finish starts to tanish or chip over time, it can be re-plated to return to its original luster. A gold plating service can re-plate and restore a gold finish and prevent anyone from seeing the other metal that sits below the surface.

For the metals commonly covered by a plating of gold, their atoms diffuse into the gold layer itself. This diffusion happens over time and is what causes a gradual dulling of the gold color. The surface will eventually tarnish, often over the course of years.

Re-plating safely returns your gold color.

WEARING DOWN

Gold plating eventually wears off, but the rate of tarnish can vary greatly depending on the piece.

There are three main factors that determine how quickly your gold plating will go:

- Thicker plating lasts longer because there is more to wear away.

- Gold has an affinity for some metals. Gold holds tighter to silver and titanium than it does to copper or nickel, and the tighter this hold, the longer the plating will last.

- The more an object is rubbed or used, the faster its plate will wear away.

CONCERNS WITH GOLD ELECTROPLATING

Gold electroplating is a very safe process when done by professionals. One concern with gold plating, however, is that it masks the other metals. If you have a metal allergy, you may be exposed to the allergen as the gold plating tarnishes and the coating wears away.

Nickel is the main cause of metal allergens, so an allergic reaction may appear once the nickel is exposed. Re-plating can prevent the allergic reaction for some time.

In comparison to other forms of plating, the cost of gold plating can also be somewhat high. Fluctuating gold prices have a major impact on the cost of gold plating at any given time. For more information on current gold prices, contact Sharretts Plating.

Gold Plating FAQs

What Is Gold Electroplating?

Gold electroplating is a method for placing a thin coating, or layer, of gold onto the surface of another metal object. The gold electroplating process involves electrodeposition, in which an electric current is passed through a liquid electrolyte solution containing dissolved gold ions and other chemicals. This causes the ions to adhere to the surface of the object, resulting in the formation of a protective gold coating.

What are the Benefits of Electroplating With Gold?

Gold contains a number of unique properties that make it ideally suited for numerous plating processes. Plating with gold also offers a host of valuable functional benefits for industrial manufacturers including:

- Preventing corrosion: Gold is the least reactive of all the metals. A gold coating will enhance the workpiece’s ability to resist corrosion, which increases the product’s longevity and lengthens the time until a replacement is required.

- Promoting electrical conductivity: A lesser-known aspect of gold is its natural ability to conduct electricity, which makes it a good choice for many electronics manufacturing applications.

- Increasing wear resistance: Gold will improve the durability of a product by increasing its resistance to normal wear and tear, which is an important characteristic in heavy-use environments.

- Protecting against extreme heat: Gold plating can create a “heat shield” that will safeguard the substrate against damage caused by exposure to elevated temperatures.

Hard Gold vs. Soft Gold for Plating

Hard gold plating entails the deposition of gold alloyed with another metal to alter and enhance its properties. Soft gold is essentially pure gold without alterations. Factors to consider when choosing between the two include bonding, corrosion resistance, temperature vs. contact resistance, appearance and wear resistance. Learn More Here

What Electronic Parts & Components Require Gold Electroplating?

Electronics are the main consumer of gold. For reliability in all climates hot or cold, wet or dry, gold is employed to withstand corrosion, wear and abrasion, while maintaining its remarkable conductivity and low contact resistance. The main electronic components requiring gold are:

- Connectors

- Contacts

- Switches

- Use as a semi-conductor for inter-connecting various parts on printed circuit boards, e.g. transistors.

Dentistry is a common application for gold plating. Its uses are for:

- False Teeth

- Crowns

- Caps

Gold is electroformed from a mold created from the plaster impressions taken during a normal office visit.

An up and coming use of gold is as a catalyst. New research shows that gold can be a more effective catalyst than platinum due to its low temperature during catalysis versus platinum. Thus gold plating is being used in new catalytic converters and tested for the next generation of automobiles. Miniaturization is on the forefront of gold use. Engineers are now able to build newer materials faster and repair old worn down substances with much more ease.

The creation of microelectronic mechanical systems (MEMS) allows doctors and surgeons to perform non-invasive surgery and implant long-lasting devices to improve and sustain a being’s health. Gold seems not to cause the immune system to react negatively or cause an auto-immune response. Next to the last major user for gold plating is Space (Aviation/Aeronautics). Used in rocket engines as well as heat shields from solar radiation and the highly corrosive environment. If you need gold plating services, contact us for a free quote!

What Are the Alternatives to Gold Plating Coatings?

For companies that find the cost of plating with gold to be prohibitive, other more cost-effective alternatives include palladium, silver and certain tin and nickel alloys. While plating with these metals can provide nearly the same results as when electroplating with gold, metal finishing experts usually recommend employing a gold electroplating process whenever possible. That is because a gold electroplating solution delivers the best long-term results, which can actually make it more cost-effective over time. These less expensive metals also cannot match gold when it comes to aesthetic appeal.