While electroplating is typically known as a metal-on-metal process, some manufacturing applications require plating onto plastic materials. The reasons are often functional, such as metalizing a plastic substrate to enable it to conduct electricity or to harden and protect the surface.

While electroplating onto plastic offers a variety of benefits, it is often more difficult to execute successfully than plating metal objects. One of the biggest challenges of plating onto plastics is creating a bond between the plastic substrate and the metal coating. Attaining a successful outcome usually requires implementing several additional surface preparation steps to ensure sufficient adhesion and a uniform coating distribution.

Which Plastic Materials Make the Best Electroplating Substrates?

Plastics take many forms, some of which are more suited for certain applications. Depending on the plating application and properties needed, these plastics may be used for metal finishing.

Thermoplastic vs. Thermoset Materials

Thermoplastics and thermoset materials are two different types of polymer powders used to manufacture various goods and products. The biggest difference between the two is their different responses to heat. Thermoplastic materials can be heated, molded, cooled, reheated and remolded as many times as necessary without chemically changing the material.1 On the other hand, heat strengthens thermoset materials, though they can’t be reheated or remolded after they’ve been formed.1

Both materials have valuable uses across various industries, though thermoset materials are much more durable and resistant to corrosion and heat. After initial heat treatment, thermoset materials are unaffected by additional heat exposure while thermoplastic materials tend to warp and melt when exposed to extreme heat.1

Amorphous vs. Semi-Crystalline Plastic Materials

A plastic’s porosity can impact the electroplating process, which is extremely important to consider when using thermoplastics for metal coating. Thermoplastics can be divided into two subcategories2 — amorphous and semi-crystalline — with different molecular structures. For example, amorphous thermoplastic is an unstructured material that’s stiff, clear and solid and has low shrinkage. Semi-crystalline contains some amorphous material, though they’re more systematized and crystal-like.2 This structure makes semi-crystalline materials tougher and more heat resistant.

Because of the difference in molecular structure, the melting and molding process for amorphous and semi-crystalline materials will vary.2 When molding, the material needs to melt uniformly to mold correctly or the plastic may have inconsistencies. Inconsistencies are more likely in semi-crystalline thermoplastics, though vacuum impregnation may be a solution to those challenges.

Common Plastics for Metal Finishing

The properties of some plastics make them more amenable to electroplating than others. While some plastics have natural success when used for plating, others need to be blended with other plastics to reach a desirable “plateability.” Here are some of the most common plastics used in metal finishing and some examples of plastics that can be blended for plating.

Polycarbonate (PC)

Polycarbonate is regarded among the best plastic material for metal finishing. PC is an incredibly strong material that offers impact resistance. In addition to being stronger than glass and acrylic,3 PC is extremely versatile and offers high design flexibility. This material can be easily molded, thermo-formed or cut without pre-forming.4 PC materials come in sheets, tubes or bars and are crystal clear or can be colored to achieve a desired design.

Polycarbonate is commonly used in construction, automotive, technology and aerospace applications. PC works well for metal finishing and electroplating.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer widely regarded as the first plastic material used for electroplating. The process was specifically developed for the automotive industry in the 1960s and is still practiced today.

Examples of ABS products include:

- Novodur P2MC

- P2K

- Polylac

- Cycolac

- Toyolac

- HI 121

ABS consists of various embedded properties that facilitate metallization in high-volume production applications. Other uses for plating onto ABS include bathroom accessories, electrical fittings and hardware items.

Acrylonitrile Butadiene Styrene-Polycarbonate (ABS-PC)

Acrylonitrile butadiene styrene-polycarbonate (ABS-PC) is a widely used industrial thermoplastic. Its demand results from its ability to combine the strength and heat resistance of PC with the flexibility of ABS, which makes ABS-PC ideal for applications within the telecommunications, electronics and automotive industries.

Examples of ABS-PC products include:

- Bayblend T45, T65 andT85

- Cycoloy

- Xantar CCM 206

In recent years, demand for ABS-PC has grown due to the automotive market’s use in door handles, trims and more. The manufacturing advantage of ABS-PC products, like Cycoloy, is they offer a lighter weight than metal and lower cost for milling and polishing.

Acrylic or Polymethyl Methacrylate (PMMA)

PMMA, widely known as acrylic, is a popular plastic material that bonds well with adhesives. Acrylic can be easily thermo-formed or fabricated and is very strong and stiff.3 This material is lightweight and resistant to shattering, impact and abrasions. PMMA can be used in nearly every method for manufacturing thermoplastics,5 including electroplating.

Polysulfone (PSU)

Polysulfone is another common plastic material for plating. PSU materials are commonly used to add durability in flame retardant applications because of their high-heat-resistant properties. Polysulfone is also commonly used in medical applications or food preparation because it can withstand repeated sterilization.

Polylactic Acid (PLA)

Polylactic acid is a biobased polymer that can be plated with copper and nickel.6 PLA is strong, though it’s often tailored to achieve toughness, stiffness and heat resistance. When used for plating, it’s common for PLA to be treated to enhance the metallic adhesion.6 PLA is also melted down and used in industries such as packaging, medical and textile.

Polyether Ether Ketone (PEEK)

PEEK is often referred to as a high-performance super polymer because it’s highly chemical-, thermal- and wear-resistant.7 It’s used in the electronic, aerospace, electrical and automotive industries. This thermoplastic is considered a lightweight and cost-effective replacement for several types of metals, including stainless steel.7 Because of its impressive properties, PEEK responds well to being used in plating.

Polyphthalamide (PPA)

A member of the nylon family, metal-plated polyphthalamide (PPA) products often serve as substitutes for metal objects because of their enhanced chemical resistance, increased strength at elevated temperatures and exceptional dimensional stability.

Some examples of PPA products include Adilene and RTP 199×69949.

Polyamide (Nylon)

Nylon is a durable thermoplastic with impressive abrasion resistance, making it an ideal material for many high-friction industrial applications like bearings and bushings.3 Nylon can also be used to replace metal parts to reduce noise, wear and weight. While it’s possible to plate metals with nylon, it must be a custom-blended nylon resin rather than nylon in its basic form.

Polypropylene (PP)

Polypropylene is part of the nylon family, like PPA. PP can be used for plating if it’s in a blended form. This material is stronger than PE and is impressively flexible.8 Because of its durability, heat resistance, acid resistance and low cost, PP is one of the most produced plastics.9 PP is used to make medical devices, food containers, vehicle parts and lab equipment, among others.

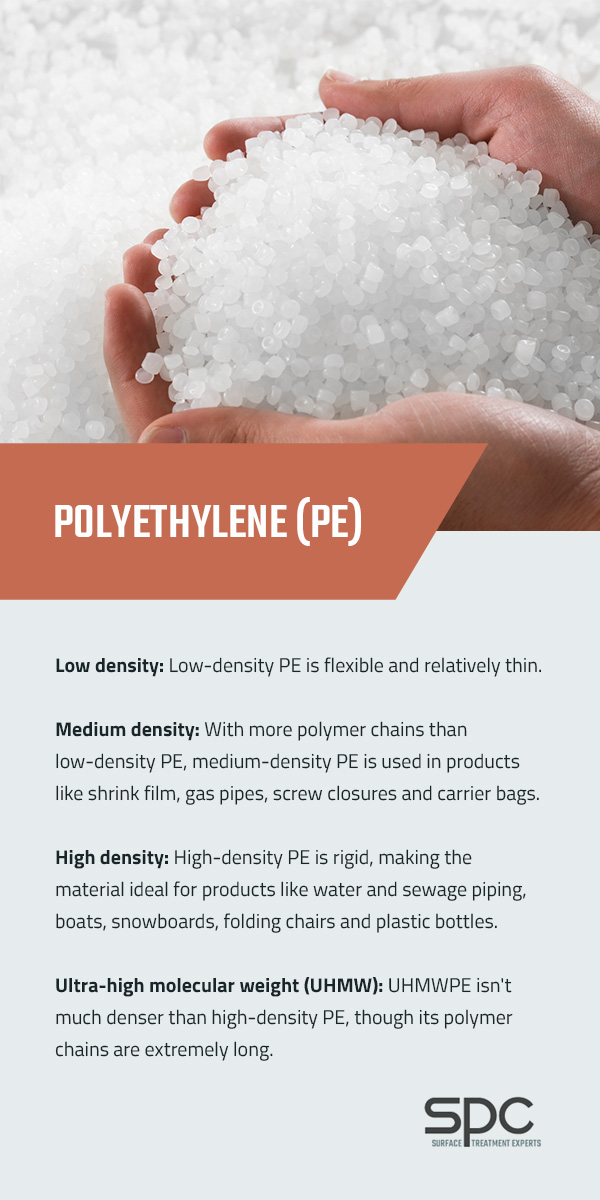

Polyethylene (PE)

Polyethylene is one of the most popular types of plastic because it can be manufactured in several different densities. Each density offers different properties, making it an ideal material for various products and applications. As the density increases, so does the number of polymer chains in the PE.8

- Low density: Low-density PE is flexible and relatively thin. This plastic is most commonly used to make products like plastic bags, disposable packaging and clear food containers.

- Medium density: With more polymer chains than low-density PE, medium-density PE is used in products like shrink film, gas pipes, screw closures and carrier bags.

- High density: High-density PE is rigid, making the material ideal for products like water and sewage piping, boats, snowboards, folding chairs and plastic bottles.

- Ultra-high molecular weight (UHMW): UHMWPE isn’t much denser than high-density PE, though its polymer chains are extremely long. Because of the polymer chain lengths, UHMWPE has more abrasion-resistant properties. The low friction of this material makes it ideal to use in products like artificial skating rinks, hydraulic bearings and seals, military body armor and spine, knee and hip implants.

Polyethylene is typically not the best plastic material for plating, even when blended in a resin, because of its anti-adhesive properties.

Polyvinyl Chloride (PVC)

PVC is a common synthetic polymer since it can be flexible or rigid and can be blended with other materials.8 This material is easy to thermo-form and fabricate and is often joined with adhesives and solvents.3 PVC is commonly used in piping systems, construction materials, plumbing products, tubing, cable insulation and much more. PVC has chemical-resistant properties, which make it ideal for many industrial applications, though it’s not normally considered plateable.

Contact SPC to Learn More About Plating Onto Plastic

As one of the leading metal finishing companies with more than 90 years of expertise, SPC can develop a customized process for plating onto ABS and other plastic materials for your specific manufacturing applications. Contact us for more information and a no-obligation quote today.

Sources:

- https://www.thomasnet.com/articles/plastics-rubber/thermoset-vs-thermoplastics/

- https://www.azom.com/article.aspx?ArticleID=17477

- https://www.grainger.com/know-how/equipment-information/kh-choose-plastic-for-manufacturing-fabrication

- https://www.acplasticsinc.com/informationcenter/r/7-different-types-of-plastic-and-how-they-are-used

- https://www.fastradius.com/resources/polymethyl-methacrylate-pmma/

- https://iopscience.iop.org/article/10.1149/2.1201609jes

- https://www.azom.com/article.aspx?ArticleID=21321

- https://www.acplasticsinc.com/informationcenter/r/7-different-types-of-plastic-and-how-they-are-used